On 27th March 2024, we were invited to the NAS (National Association of Shopfitters) & IOC (Institute of Carpenters) Members’ Day & AGM. This was held at the amazing Carpenters Hall in the City of London.

The day served as a pivotal gathering where members could connect and exchange ideas. It’s also an effective way for NAS & IOC members to keep updated on industry trends & innovations. This year’s event showcased both industries’ resilience and adaptability in the face of challenging industry conditions. We’d like to thank both the NAS and the IOC for inviting us along to such a successful event!

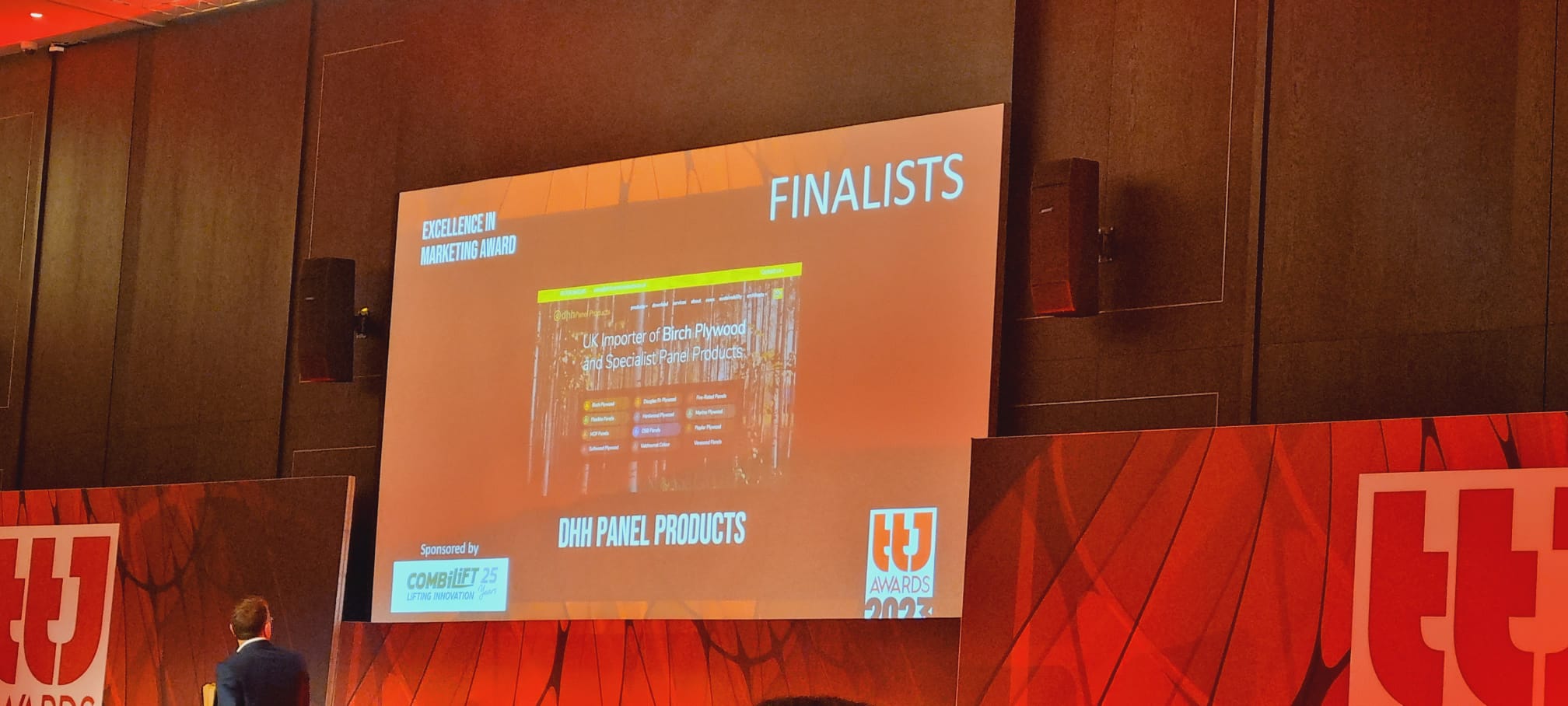

The success of the Members’ Day owes much to the generous support of sponsors. This included ourselves and Medite Smartply, who we are proud to be UK distributors for. Our colleagues from Medite were also one of the guest speakers during the day. Overall, the event enabled great networking opportunities among members.

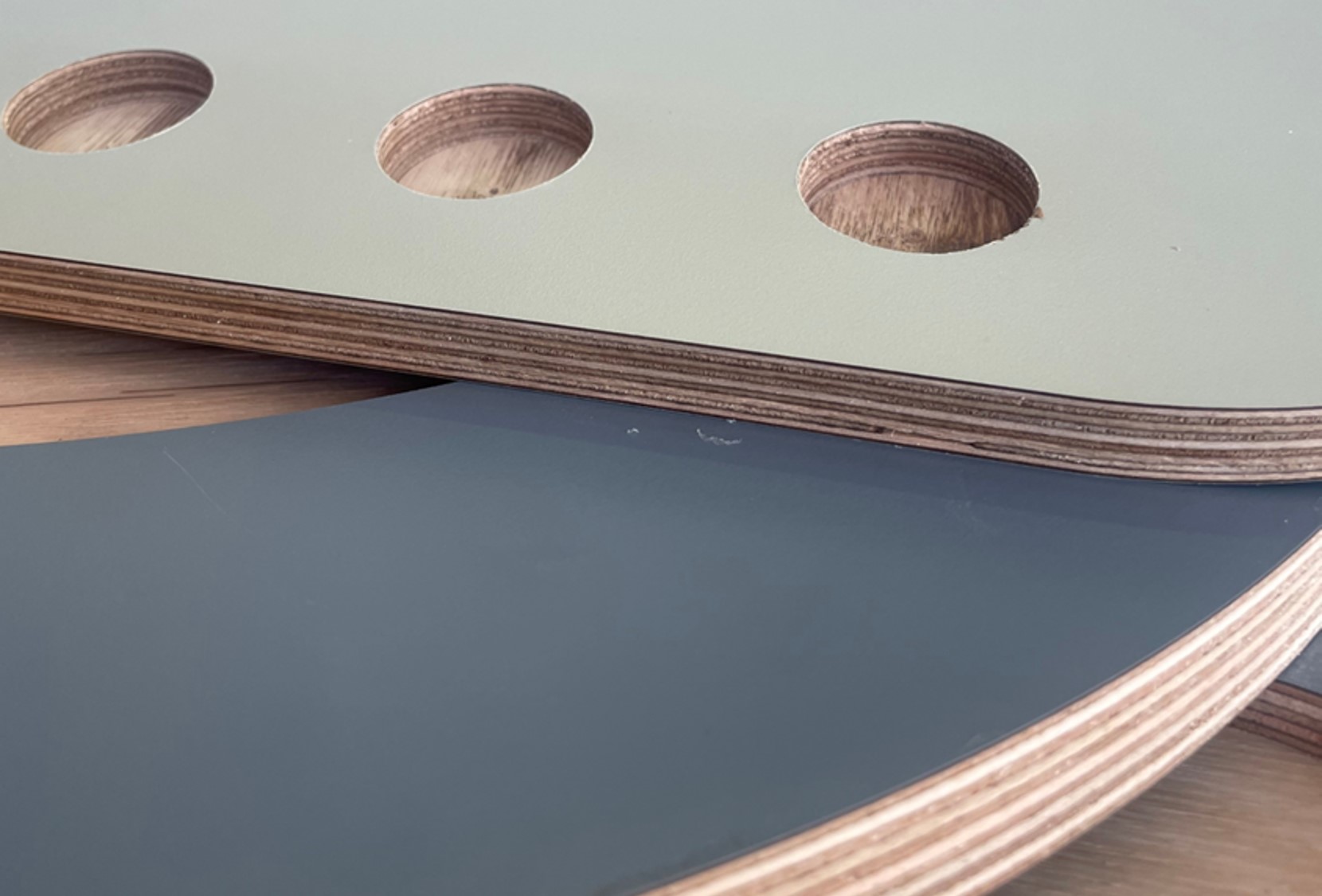

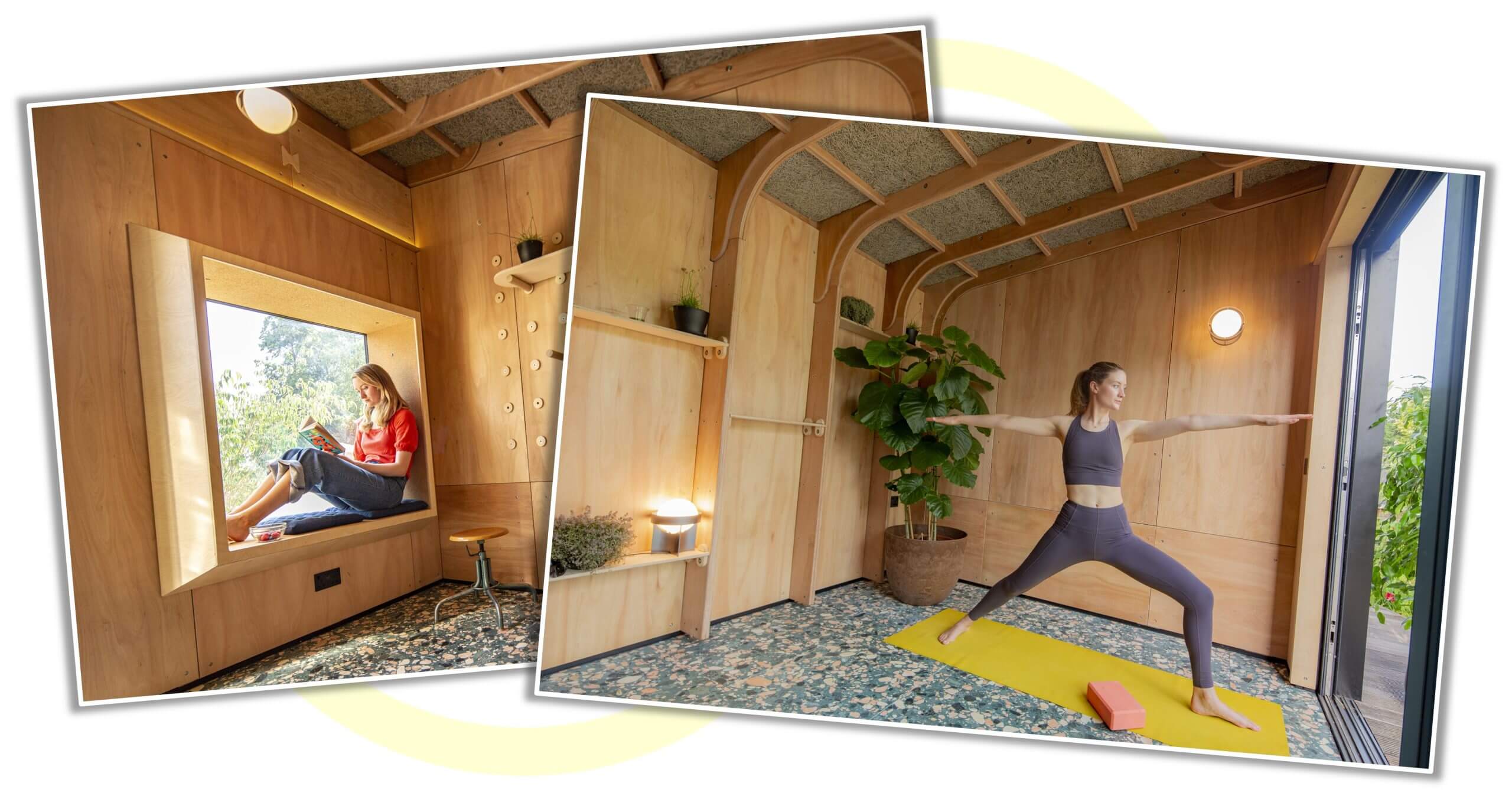

Many of the members were additionally keen to hear our updates on Birch Plywood. Some were unaware that Finnish, Polish and Latvian Birch Plywood products still continue to be available within the UK. As a reputable importer, we continue to work proactively to ensure that no products from sanctioned countries enter our supply chain.

We also had engaging conversations about alternatives to Birch Plywood. This includes Poplar Plywood from Panguaneta, which can come with a birch veneer face. There is also the option of other Veneered species, and pre-lacquered plywoods too.

Creating a Dynamic Partnership

The strategic partnership between the NAS and the IOC is starting to stand out as a symbol of innovation. This new collaboration allows the shopfitting and carpentry industries to combine their expertise, resources and networks. Moving forward, this synergistic relationship helps magnify their influence; and ultimately benefits the members of both organisations.

Together, they pioneer initiatives that advance craftsmanship and uphold industry standards. They also help foster professional development between members. The combined Members’ Day facilitated this exchange of knowledge, best practices, and cutting-edge techniques. This empowers members to stay ahead of the curve in an ever-evolving landscape.

As a unified force they hope to innovate, inspire & elevate standards. We wish both organisations every success with their new collaboration.

National Association of Shopfitters Website | Institute of Carpenters Website